Fluid Energy Controls Surge Suppressors

Fluid Energy Controls Surge Suppressors are designed to dampen the pressure surges caused by rapid closing and opening of flow control valves in any system handling liquids. This reduces the possibility of costly damage to the pipelines, leakage, loosened pipe fittings and downtime.

FEC Surge Suppressor Benefits

- Protects pipes, valves, fittings, meters, and in-line instrumentation from destructive pulsations, surges, cavitations, thermal expansion, and water-hammer.

- Creates steady and continuous flow when dosing, blending or proportioning additives.

- Ensures accuracy, longevity, and repeatability of in-line meters.

- Enables uniform application of material in spraying and coating systems.

- Reduces agitation, foaming, splashing and degradation of product.

- Provides liquid energy storage for emergency valve closure and other equipment shutdown.

- Reduces overall energy cost with continuous fIow, rather than start/stop flow.

- Operates as a reservoir for make-up fluid.

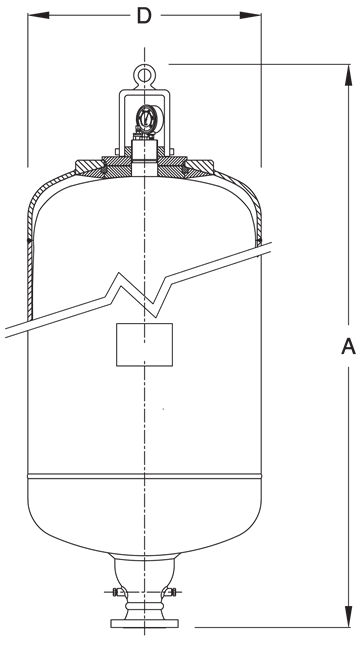

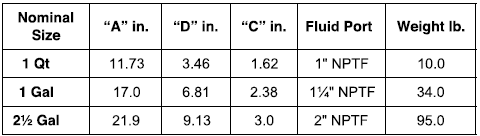

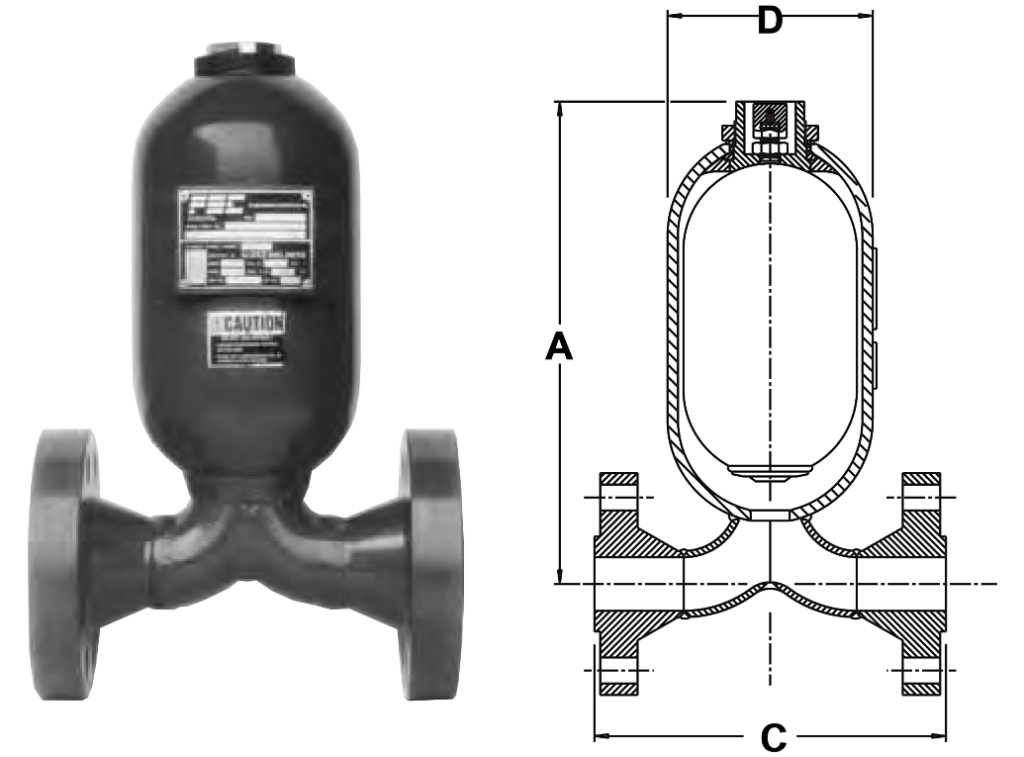

Surge Suppressor 2.5 Gal — 15 Gal

Specifications

- Design Pressure : 225 PSI, 275PSI, 500 PSI

- Temperature: -20 F to +200 F

- Bladder Material : Buna-N, Viton, EPR, Hydrin, Butyl, Low Temp Buna-N

- Shell Material : Carbon Steel, 304SS, 316SS

Features

- Certification : ASME CE/PED, CRN, SELO, NR-13, AS-1210, and DOSH available upon request.

- Capacity : 5 Gal to 15 Gal (9.5L to 57L)

- Gas Port : Schrader Gas Valve standard

- Fluid Connection: ANSI RF Flange

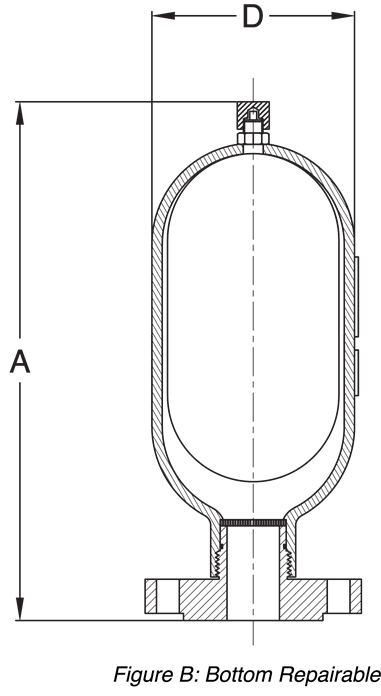

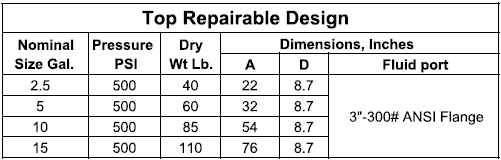

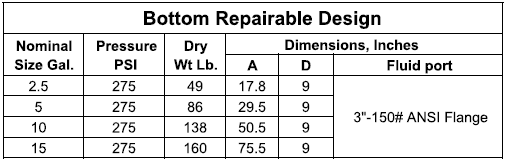

Dimensions

Surge Suppressor 25 Gal — 120 Gal

Specifications

- Design Pressure : 225 PSI, 275PSI, 500 PSI

- Temperature : -20 F to +200OF

- Bladder Material : Buna-N, Viton, EPR, Hydrin, Butyl, Low Temp Buna-N

- Shell Material : Carbon Steel, 304SS, 316SS

Features

- Certification : ASME CE/PED, CRN, SELO, NR-13, AS-1210 and DOSH available up on request

- Capacity : 25 Gal to 120 Gal (95L to 454L)

- Gas Port : MS Style Gas Valve standard

- Fluid Connection: ANSI RF Flange

- Top Repairable design for ease of maintenance

- Wetted parts : Stainless Steel

- Carbon Steel shells available with internal epoxy coating

Dimensions

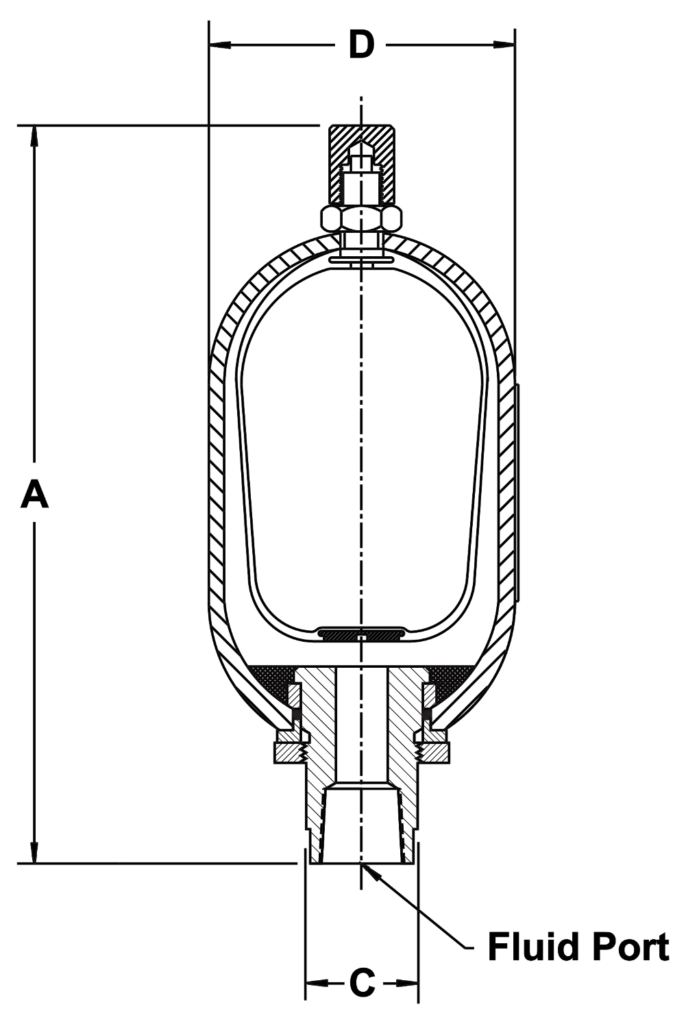

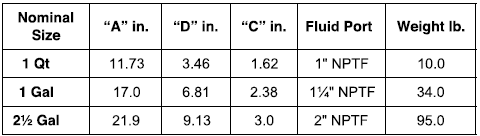

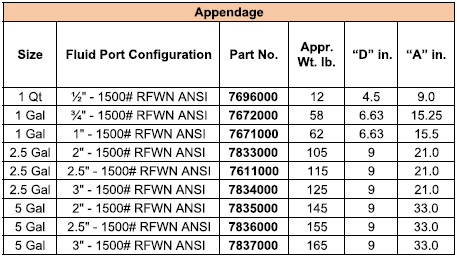

High Pressure Pulsation Dampeners

Positive Displacement (PD) pumps create pulsation and hydraulic shock due to the reciprocating nature of their stroking action, potentially damaging the entire pumping system. Pulsation Dampeners remove hydraulic shock and reduce the pressure and flow fluctuations. This enhances the all-around performance and reliability of fluid handling equipment in industrial, chemical transfer, and precision metering applications

Increase productivity, safety, reliability and efficiency.

Decrease maintenance and operating costs.

The Fluid Energy Controls Pulsation Dampeners are specially designed for use with high pressure reciprocating piston and plunger pump systems. The nitrogen gas pre-charged bladder inside the Pulsation Dampener dampens the pressure pulsations created by the reciprocating action of the pumps.

The dampeners offer the following benefits

- Increase pump efficiency

- Reduction in pump downtime

- Reduction in noise and vibration

- Reduction in costly damage to the system components

The Pulsation Dampeners are constructed of carbon steel and internally coated to resist corrosion. The port assembly is of stainless steel 300 series construction.

- Maximum operating pressure: 3,000 PSI

- Replaceable bladder — can be changed in a few minutes

- Many bladder compounds available

Industries Served

- Chemical Process

- Pulp, Paper and Textile

- Gas, Oil, and Petrochemical

- Biotech / Pharmaceutical

- Paint and Coating

- Food and Beverage

- Consumer Products

- Water Treatment

Industries Served

- Chemical Process

- Pulp, Paper and Textile

- Gas, Oil, and Petrochemical

- Biotech / Pharmaceutical

- Paint and Coating

- Food and Beverage

- Consumer Products

- Water Treatment

Fluid Energy Controls’ pulsation dampeners are designed for oilfield application to minimize pressure pulses generated by

positive displacement pumps. The dampeners are built to withstand high pressure as they smooth out the harmful pressure pulses originating from the pump. They are especially suitable for water and petrochemical applications.

Features

- Flexible bladder design effectively reduces pump pulsations, vibrations and noises

- No poppet and spring to restrict flow of viscous process liquids

- Top repairable design for ease of maintenance

- Designed and stamped per ASME Sec. VIII, Div. 1. CE/PED, CRN, NR-13, SELO, and DOSH. Other certifications also available

- Buna-N bladder with integral anti-extrusion button for long life. Viton and other compounds available.

- All wetted parts are coated carbon steel or Stainless steel

- Prolongs service life of pumps, valves, instruments, and pipe joints

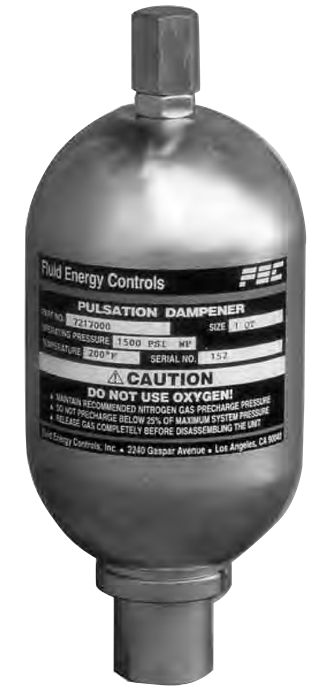

Stainless Steel Pulsation Dampeners

Fluid Energy Controls 316 Stainless Steel Pulsation Dampener is specifically designed to satisfy the needs of petrochemical, reverse osmosis and water processing industries. It can effectively dampen the damaging pulsations caused by the reciprocating pumps. This reduces the possibility of costly damage to pipelines, instrumentation, loosened pipe fittings, leakage and downtime.

Features

- Significantly reduces pump pulsations

- Reduces pump vibration and noise

- Increases pump service life; reduces wear and fatigue on pump’s internal parts

- Repairable in the field

- All wetted parts are of 316 series stainless steel for protection against corrosion

Specifications

- Volume — 60 cubic inches

- Maximum working pressure — 1,500 PSI

- Operating temperature range — -20°F to +185°F

- Diameter — 4.5 inches

- Length — 11 inches

- Port — 1″ NPT (female)

- Weight — 10 lbs.

InstalIation,operation and maintenance are simple

Installation : Install the dampener as close as possible to the discharge port of the pump.

Operation

- Precharge dampener with dry Nitrogen to approximately 70 – 80% of the system operating pressure.

- Check the precharge pressure periodically.

Ordering Information

| Bladder Compound | Part Numbers | |

| Pulsation Dampener | Repair Kit | |

| Viton | 7217000 | 5250016 |

| Buna-N | 7218000 | 5250017 |

| EPR | 7219000 | 5250017 |